The instruments can be configured for almost any gas or gases, including water vapour, hydrocarbons, O2, CO2, N2, H2 and He.

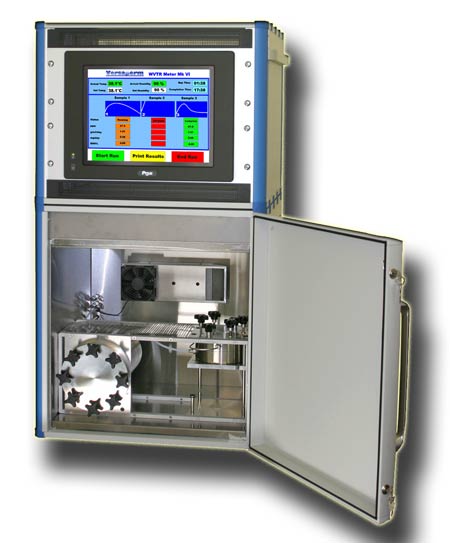

Up to three standard sized

chamber modules can be included, either for flat samples such as films, or for

containers. These can be provided in a range of sizes. The chambers are housed in

a temperature controlled cabinet, an may be heated, chilled or otherwise controlled if required.

The range of gases that is suitable for permeability measurement

is limited only by the sensors being commercially available.

Although we manufacture some sensors ourselves, for most gases

we use the current "best available" sensors for

any application. We have alliances with many of the leading

gas detection companies which operate around the world.

Using our WVTR to measure permeability / diffusion rates

As well as measuring the permeability of water vapour our system meter can be configured to measure the permeability for a range of gases including Helium, hydrocarbons, Oxygen and CO2 (Carbon Dioxide)

For equipment to measure moisture permeability click hereFor background information on permeability click here

For information on applications click here

For details of our huge sensor range click here

Comparison of Typical WVTR’s - (Relative to Polyamide at 100%)

Best Vapour-barrier materials |

WVTR Relative Permeability based on Polyamide at 100% |

Cold Form Foil |

0 |

CTFE |

0.02 |

COC |

0.24-0.29 |

Polychlorotrifuoroethylene (PCTFE or Aclar) |

0.16 |

Polyvinylidene chloride (PVDC or saran) |

0.2 |

High-density polyethylene (HDPE) |

1.2 |

Polypropylene (PP) |

1.6 |

Good Vapour Barrier materials |

WVTR |

Low-density polyethylene (LDPE) |

4.8 |

Polyethylene terephthalate (PET) |

5.2 |

Low vapour-barrier materials |

MVTR |

Polyvinyl choride PVC |

16 |

Acrylonitrile copolymer (Barex) |

20 |

Polyamide (PA or Nylon) |

100 |

Please contact us to discuss how we can meet your needs.