For information on permeability testing click for food click here

For a press release on Modified Atmosphere packaging click here

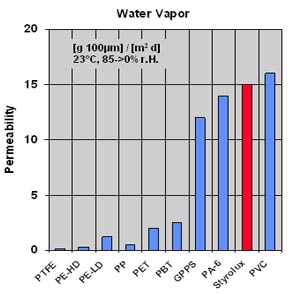

Cling film or Plastic Wrap (called Glad wrap and Saran in some countries) is a thin plastic film used for sealing food to keep it fresh. The most critical characteristic of this film is its vapour (vapour) permeability - with different foods requiring different vapour permeabilities with respect to gases such as Oxygen and CO2. Choosing materials with the right permeability, together with quality control testing is crucial.For most foods shelf life is largely controlled by the Oxygen vapour permeability of the wrap – sometimes it needs to be excluded, and at others it is vital to ensure it is present, Usually the rate at which the Oxygen needs to flow through the film must be controlled to allow the food to perspire or respire. Even with frozen foods, packaging with the wrong permeability causes freezer burn and “off” smells.

A good example of how a food's packaging can preserve freshness and increase shelf-life is strawberries (or raspberries). Both of these are commonly packaged in perforated-top containers. However the fruit “respires” within and the concentration of CO2 rapidly approaches the critical 10-15% level necessary to inhibit Botrytis growth.

A good example of how a food's packaging can preserve freshness and increase shelf-life is strawberries (or raspberries). Both of these are commonly packaged in perforated-top containers. However the fruit “respires” within and the concentration of CO2 rapidly approaches the critical 10-15% level necessary to inhibit Botrytis growth.

For equipment to measure permeability click here

For background information on permeability click here

For an article on water vapour and food click here

For an article on freezer burn click here

Vapour permeability is the measure of how strongly a material can resist the barrier passage of any gas (such as water vapour, Oxygen, CO2 or a hydrocarbon). Vapour permeability dramatically affects the physical characteristics of most products and materials, from outdoor clothing to missiles and from pizza to industrial seals.