Or how flavour & shelf life changes between a plastic bottle and a can and is leading to a "Designer revolution" in materials

It is well known that that flavour of the fizz changes between a bottle and a drinks can and the shelf life changes as well. Surprisingly, these differences arise from exactly the same cause - Vapour Permeability. Fortunately, although the science behind this is "challenging", there is a simple solution that helps manufacturers deal with it. And a revolution in materials design is on the way.

It is well known that that flavour of the fizz changes between a bottle and a drinks can and the shelf life changes as well. Surprisingly, these differences arise from exactly the same cause - Vapour Permeability. Fortunately, although the science behind this is "challenging", there is a simple solution that helps manufacturers deal with it. And a revolution in materials design is on the way.

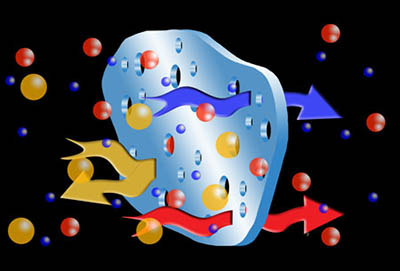

Both flavour and shelf-life problems are caused because carbon dioxide permeates out through the material sides of the plastic bottle, the cap and the can. It does this at different rates so, within twelve weeks, a plastic bottle can lose up to 15 percent of its carbon dioxide fizz!

The answer is to determine the precise vapour permeability of the finished bottle or canned product during both the design and quality control stages. The first measurement allows you to find or develop the best material for the product – and different drinks often need different materials. Ginger ale, for example, has almost twice the carbonation of most colas. The second stage - quality control, allows you to identify and minimise the inevitable drift of materials away from their specification, thus preventing problems before they happen.

Modern equipment is fast, accurate and can measure the vapour permeability of each component either separately, or as a finished bottle, can or carton. Due to changes during the manufacturing process, a container may be only a quarter as effective a barrier as the material in a flat form!

Modern equipment is fast, accurate and can measure the vapour permeability of each component either separately, or as a finished bottle, can or carton. Due to changes during the manufacturing process, a container may be only a quarter as effective a barrier as the material in a flat form!

Pressure and temperature can both be controlled using an array of different sensors, using different physical principals. This enables our equipment to characterise an ever expanding range of materials, compounds, containers, products and laminates.

Perhaps surprisingly there is a problem with drinks cans as well. Despite modern developments in can-lining, carbon dioxide actually dissolves the metal through the vapour permeability of its coating. This can be measured using the same Versaperm equipment.

When plastic bottles were introduced just after WW2 (1947), they were hailed as wonder product – and twenty five years later when PET bottles reached the market they were thought to be ultimate answer for fizzy drinks.

Now, once again we are on the brink of a revolution and are about to undergo an entire sea change - with the potential for improving the shelf life (possibly ten times longer for fizzy drinks) as well as enhancing the quality and taste. We call it the "Designer Coating Revolution," and it has already started. It will change the way in which drinks are bottled and affects both fizzy and still drinks.

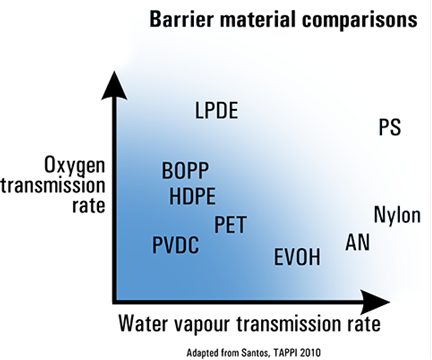

The solution began with the development of a series of vapour permeability controlling coatings and materials. These can be effectively laminated together into a single material in such a way that their vapour permeability and strength qualities combine into a unique material that has been optimised for an individual and specific-carbonated drink product.

Until the 1990s it wasn't technically or commercially feasible to do this and get the perfect combination of vapour permeability to various gases combined with rigidity and strength. This was because measuring the vapour permeability involved sealing a small cup with a material (e.g. PET ), weighing it very accurately, then reweighing it weeks or months later to determine the tiny weight change caused by the escape (or ingress) of vapour through the material.

Fortunately, the latest ranges of devices we design and manufacture, use different measurement techniques that count the rate at which individual molecules of gas or vapour permeate in or out. New detectors produce measurements that are fast and highly accurate and this cuts the timescale (and costs) from a period of months down to a few hours. This makes testing of different materials to produce a designer coatings for a specific product with its various vapour permeability requirements has become easy.

Fortunately, the latest ranges of devices we design and manufacture, use different measurement techniques that count the rate at which individual molecules of gas or vapour permeate in or out. New detectors produce measurements that are fast and highly accurate and this cuts the timescale (and costs) from a period of months down to a few hours. This makes testing of different materials to produce a designer coatings for a specific product with its various vapour permeability requirements has become easy.

The result is designer materials with vapour permeability rates optimised for the formulation of a specific brand of drink. The first such bottles are already on the market.

Technical note: In beer, carbonation depends on extra factors. Most common beers are carbonated by forcing CO2 into the liquid but micro-brews are often carbonated by the brewer's yeast and sugar.

Click here for an article on Designer coated materials for fizzy drinks