Today, laboratories have to characterise and measure an ever expanding range of materials, compounds, containers and laminates in the never-ending search for new technical and marketing features.

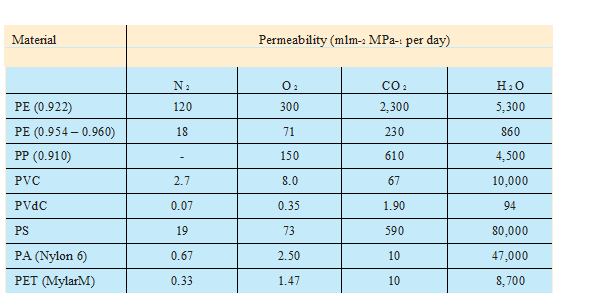

In real-world applications many of the most important Materials characteristics are controlled by vapour permeability - for example, materials handling, printability, the ability of packaging to protect the contents, and even just stopping paper jamming in the photocopier.

In real-world applications many of the most important Materials characteristics are controlled by vapour permeability - for example, materials handling, printability, the ability of packaging to protect the contents, and even just stopping paper jamming in the photocopier.

Vapour Permeability critical affects properties such as the shelf life of pharmaceuticals and foodstuffs. Unfortunately Manufacturing processes such as heating, forming and bending can change the permeability by a factor of x4! which means that results simply can’t usually be estimated from a material’s properties but materials must be tested directly. For information on Vapour Permeability on Wikipedia click here For equipment to measure permeability click here For information on permeability testing click here