Because of their excellent mechanical, physical and vapour permeable properties, liquid crystal polymers are typically used in multilayer film where they add strength and other characteristics to the overall abilities of the film.

Because of their excellent mechanical, physical and vapour permeable properties, liquid crystal polymers are typically used in multilayer film where they add strength and other characteristics to the overall abilities of the film.

LCPs have the lowest oxygen permeability of common packaging barrier films, especially at high humidities. They add high impermeably to films for gasses such oxygen, water vapour, carbon dioxide, flavours and aromas. They can be produced in both clear and transparent formats and create excellent mechanical strength, even at high temperatures; they also offer impressive chemical resistance, inherent flame retardancy and weatherability.

Even at relatively high temperatures liquid-crystal polymers are usually largely inert to most chemicals, including strong acids and bases. They are resistant to stress cracking and provide good hydrolytic stability in boiling water.

These thermotropic thermoplastics have an highly crystalline structure (though the order is somewhat less than regular solid crystals), they can be biaxially oriented and thermoformed. They may be further reinforced using materials such as glass or other minerals.

Liquid crystal polymers are available in a wide range of types, from sinterable high temperature materials to injection moldable compounds. They can be welded, and offer a high Z-axis coefficient of thermal expansion. Examples include Kevlar, PET and Vectran.

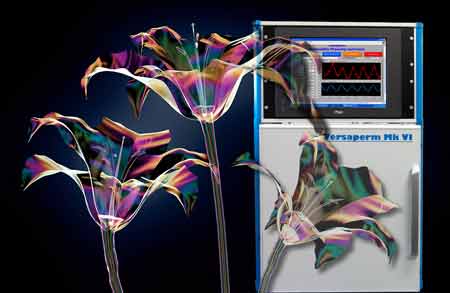

Mesogen (i.e. compounds that display liquid crystal properties) fall into two groups - disordered solids or ordered liquids and in both groups the vapour permeability depends on the ordered packing of their polymer chains. Mesogens form from an unique state of matter that exhibit both solid- and liquid-like properties. Measuring the vapour permeability of these films is often critical as this allows users to identify and correct problems and imperfections in both the materials themselves and in the manufacturing processes that produce them. Our vapour permeability measurement equipment can be used on either LCP material samples, finished or formed components and even on fully finished products. It can also, optionally, measure the permeability of LCPs for any and all general gases or vapours.

LCPs are used in the food, chemical, healthcare, packaging electrical, electronic and other industries. They are suited to microwave frequency electronics due to their low relative dielectric constants and low dissipation factors.

Click here for a press release on liquid crystal polymers

Click here for the Wikipedia article on liquid crystal polyemers - LCPs

Click here for Wikipedia's article on mesogens

Click here for Science Direct's page on LCP's

Click here for Google Scholar's latest list of articles on liquid crystal polymers