Choosing materials with the right permeability can dramatically reduce waste in business and industry. Not only that but it can cut costs, improve packaging and help you to improve the environment.

It can prevent foods from rotting early, pharmaceuticals from loosing potency, electronics from jamming and packaging from lacking punch.

To help to overcome this problem of business waste we have introduced a new version of our permeability meter for industry - and it offers not just enhanced sensitivity but is well over 100 times faster than traditional gravimetric techniques.

The new computerised meter can measure the vapour flow across either a sample of a business material, or a finished industrial product, sometimes in as little as 30 minutes. Accuracy depends on the exact sensor used as well as the gas under test but is commonly in the PPM range and is in the PPB range for some materials.

For equipment to measure permeability click here

For equipment to measure permeability click here

For information on permeability testing click here

For background information on permeability click here

Permeability - the measurement that reduces industrial waste

Permeability - the measurement that reduces industrial waste

- from food to O-rings and from packaging to electronics

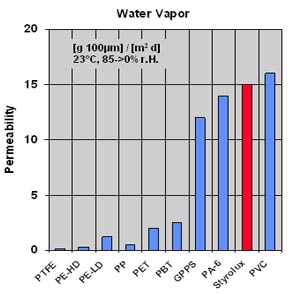

Vapour permeability is the measure of how strongly a material can resist the barrier passage of any gas (such as water vapour, Oxygen, CO2 or a hydrocarbon). Vapour permeability dramatically affects the physical characteristics of most products and materials, from outdoor clothing to missiles and from pizza to industrial seals.