Solvents are widely used throughout both industry and the home in extraordinarily diverse applications. Unfortunately they are very good at finding their way into areas they shouldn't be! Many materials that are largely impervious to solvents as liquids can be highly permeable to them in their gaseous state.

Solvents are widely used throughout both industry and the home in extraordinarily diverse applications. Unfortunately they are very good at finding their way into areas they shouldn't be! Many materials that are largely impervious to solvents as liquids can be highly permeable to them in their gaseous state.

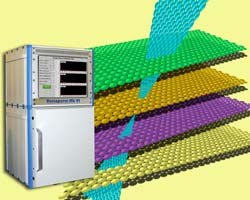

Our permeability meter can measure the permeability of materials to almost all solvents - either using flat samples of the material, or containers or finished components.

Many solvents are hydrocarbon based and we have a range of specialist sensors for these. Common solvents include: Benzene, Cycloheptane, Cyclohexane, Cyclohexene, Cyclooctane, Cyclopentane, Decahydronaphthalene, Diesel fuel, Dodecane, Drip gas, Durene, Heptane, Hexane, Hydrocarbon mixtures, Kerosene, Limonene, Mesitylene, Methylcyclohexane, Mineral spirits, Mineral turpentine, Naphtha, Naphthenic oil, Octadecene, Pentane, Petroleum ether, Toluene, Tridecane, Turpentine, White spirit, Xylene.

Our permeability equipment provides fast and accurate measurement - usually in the parts per million range, (parts per billion with some solvent vapours). Conventional gravimetric techniques take several days or weeks, but our equipment can produce results in as little as 30 minutes for some materials and solvents.

Permeable and semi-permeable membranes and solvent flow

Permeable and semi-permeable membranes and solvent flow

The permeability of a membrane to a solvent is caused by the ability of certain molecules or ions to diffuse. The rate of this diffusion is determined by the specific membrane as well as the pressure, concentration, and temperature of the molecules in the gases on both sides. Permeability is often the most critical factor in determining the way a product or material responds to the real world – it not only affects sealing, but also printability, handling and many other factors.

Click here for a press release on industrial permeability testing

Click here for a general article on the solvents from Wikipedia

Click here for an article on hydrocarbon permeability measurement