The vapour permeability of Linear Low Density Polyethylene (LLDPE) is a critical parameter for this widely used material which has applications across a wide range of applications such as food packaging, paperboard products, drinks cartons, snacks and heavy duty shipping.

The vapour permeability of Linear Low Density Polyethylene (LLDPE) is a critical parameter for this widely used material which has applications across a wide range of applications such as food packaging, paperboard products, drinks cartons, snacks and heavy duty shipping.

LLDPE has significant impact and puncture strength, tear resistance, elongation and resistance to cracking. It is commonly used for MAP, often as part of a multi-layer or customer-produced "designer" material.

The material is made by co-polymerization of ethylene with longer-chain olefins, allowing strong products to be made using thin extrusion coating, blown or cast film extrusion techniques where its absence of long-chain branching which allows it to produce greater elongation than LPDE. It can be both thinner and stronger than LPDE and is usually produced at lower temperatures and pressures.

The material is made by co-polymerization of ethylene with longer-chain olefins, allowing strong products to be made using thin extrusion coating, blown or cast film extrusion techniques where its absence of long-chain branching which allows it to produce greater elongation than LPDE. It can be both thinner and stronger than LPDE and is usually produced at lower temperatures and pressures.

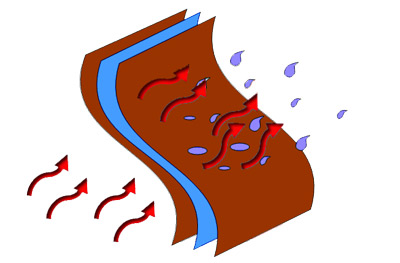

The use of polymer materials in food packaging, especially for MAP (Modified Atmosphere) Packaging, is a large and expanding market, especially for packaging which has been optimised to meet the individual vapour permeability requirements of specific products. This is critical in extending the food shelf-life and achieving the best technical-marketing solution.

The Versaperm range of vapour permeability measurement equipment provides solutions with results that are measured in the Parts Per Million (PPB) to PPB (Billion) range and optionally include additional of both temperature, pressure and humidity parameters.

The systems can measure both material samples and finished packaged products - which is important as the actual manufacturing and packaging processes can easily change the permeability of the finished, packaged product by a factor of four.

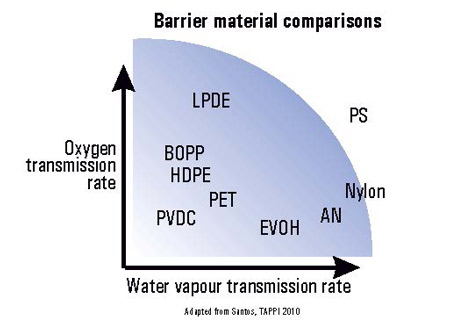

Although LPDE is an excellent material it may not be the right one for your application - a brief overview of a few alternative materials is below.

Although LPDE is an excellent material it may not be the right one for your application - a brief overview of a few alternative materials is below.

Low Density Polyethylene: An extremely versatile material with low water vapour permeability but high gas permeability.

Ethylene Vinyl Acetate, has superior sealing qualities and blended polyethylene can make a strong peelable seal.

Linear Low-Density Polyethylene (LLDPE): This has greater impact and puncture strength, tear resistance, elongation and resistance to cracking. It is commonly used for MAP.

High Density Polyethylene: with its higher softening point (than LDPE) it provides a btter a physical barrier but is not suitable as a thermoformable sealant layer, clarity is poor.

Polypropylene (PP) and Oriented Polypropylene (OPP): Gives a high water vapour and gas barrier and has excellent grease resistance.

Co-extruded Oriented Polypropylene (COPP): Is a good moisture barrier, gas barrier properties can be improved by coating it with PVdC. It can be used when gas flow is desired for MAP (Modified Atmosphere Packaging).

Inomers: Are similar to polyethylene but have a high tack and can seal through a level of surface contamination.

Ethylene Vinyl Acetate (EVA): Has high flexibility, and high permeability to water vapour and gases with excellent oil and grease resistance.

Polyvinylidene Chloride (PVdC): Used for MAP as a gas-barrier coating, often

sandwiched between other materials. It has outstanding barrier properties with low permeability to water vapour and gases.

Ethylene Vinyl Alcohol (EVOH): A moisture sensitive, very high gas-barrier material, again often sandwiched.

Polystyrene: A clear thermoplastic with a high tensile strength. It is brittle and a poor barrier to moisture vapour and gases.

High-impact Polystyrene: Opaque, thermoformable, and a moderately low gas-barrier.

PET: High clarity that forms and thermoforms well.

Using the most appropriate materials can dramatically extend the life of food products, boost quality, virtually eliminate freezer burn, reduce spoilage and thus boost profits. However it depends not just the materials you use, but on the way you make the seals – which can vary even on the same equipment on a daily basis. The best solution is to test the materials, the packaging and the finished products.