Vapour Permeability in Marine and Offshore Platforms

Introduction

Introduction

Vapour permeability — the ability of a material to allow the passage of water vapour — is a critical but often underestimated factor in the marine and offshore industries. On oil rigs and offshore platforms, poor vapour control contributes directly to corrosion under insulation (CUI), insulation failure, coating delamination and long-term asset degradation.

Understanding vapour permeability and integrating effective testing and control strategies, is therefore central to asset integrity, safety and lifecycle cost reduction.

Problems Related to Vapour Permeability in Marine and Offshore Platforms

- Corrosion of Metal Structures

- Vapour can pass through coatings or insulation, condense on cold steel or aluminium surfaces and initiate corrosion.

- Results in structural weakening, increased maintenance costs and elevated safety risks.

- Insulation Degradation

- Poor vapour barriers allow moisture absorption, reducing thermal effectiveness and increasing insulation weight.

- Impacts HVAC, refrigeration and process efficiency.

- Delamination and Coating Failure

- Vapour ingress beneath coatings causes blistering, peeling, or composite delamination.

- Leads to shortened service life and unplanned downtime.

- Mould and Mildew Growth

- Confined marine environments suffer from humidity build-up when vapour management is poor.

- Results in biological growth, odours and health hazards for crew.

- Electrical Failures

- Vapour ingress into electrical systems causes corrosion or short circuits.

- Can compromise navigation, communications and safety systems.

Applications of Vapour Permeability in Marine Engineering

- Marine Coatings and Paints

- Controlled vapour permeability prevents blistering while avoiding condensation beneath coatings.

- Thermal Insulation Systems

- Vapour barriers (e.g. aluminium foil layers, polymer wraps) integrated with insulation prevent moisture ingress.

- Crew Clothing and Gear

- Waterproof but breathable membranes (e.g. Gore-Tex) balance comfort and protection.

- Composite Marine Structures

- Fibre-reinforced polymer (FRP) hulls and decks require vapour protection to prevent osmotic blistering.

- HVAC and Ventilation Systems

- Materials with controlled vapour permeability improve air quality and prevent condensation.

- Ship Interiors and Accommodations

- Vapour-permeable membranes regulate internal humidity, enhancing comfort and durability.

Technical Lessons Learned: Vapour Permeability and CUI on Offshore Platforms

Technical Lessons Learned: Vapour Permeability and CUI on Offshore Platforms

- Barrier Integrity Is as Critical as Insulation

- Even advanced insulations fail without effective vapour barriers.

- Must include multi-layer systems with sealed seams and penetrations.

- Joints and Fittings Are High-Risk Zones

- Vapour ingress occurs at valves, flanges, supports and elbows.

- Prefabricated insulation covers and vapour-sealing mastic improve continuity.

- Example: Gullfaks B (2024 audit) highlighted poor barrier integrity at support brackets.

- Closed-Cell Insulation Offers Superior Protection

- Open-cell materials wick moisture; closed-cell options (foam-glass, polyisocyanurate, aerogel blankets) resist vapour diffusion.

- Inspection Access Must Be Designed In

- Retrofitted inspection ports often compromise vapour barriers.

- Removable cladding or hinged insulation boxes maintain long-term integrity.

- Ambient Vapour Diffusion Can Be Enough to Drive CUI

- Cold piping systems (e.g. LNG, chilled water) are at risk even without bulk leaks.

- Offshore standards often target WVTR < 0.1 g/m²/day.

- Digital Asset Integrity Systems Improve Detection

- Thermal imaging, moisture probes and smart coatings with embedded sensors enable predictive detection.

- Digital twins and condition-monitoring platforms (e.g. Equinor’s Omnia Prevent, Echo) flag high-risk areas.

- Training And Standardisation Are Essential

- Inconsistent practices between contractors accelerate CUI.

- Standardised specifications and vapour-sealing training must be enforced across fabrication, commissioning and O&M phases

The Business Case: Vapour Permeability Testing for Offshore Platforms

Background

Corrosion under insulation (CUI) remains one of the highest contributors to unplanned maintenance costs in offshore platforms. A significant driver is water vapour ingress through coatings, insulation and barriers. Traditional inspection regimes often detect problems only after corrosion has advanced, leading to expensive remediation, downtime and in extreme cases, safety incidents.

Vapour Permeability Testing as a Preventative Measure

Modern vapour permeability testing, such as that provided by Versaperm’s Mass Spectrometer systems, enables operators to:

- Accurately measure the Water Vapour Transmission Rate (WVTR) of insulation and coatings.

- Select and validate low-permeability materials that meet offshore specifications (often WVTR < 0.1 g/m²/day).

- Identify weaknesses in supply chains, ensuring contractors deliver materials that perform as required.

- Quantify barrier integrity before installation, reducing the risk of early-life CUI failures.

Business Impact

Field data and case reviews suggest that effective vapour permeability testing, coupled with improved barrier selection and installation practices, can deliver:

- 60–75% reduction in annual CUI-related maintenance costs

- Lower insulation replacement frequency (extending from ~5 years to >12 years in some systems)

- Improved operational uptime, avoiding corrosion-driven shutdowns

- Safer working environments with fewer integrity risks

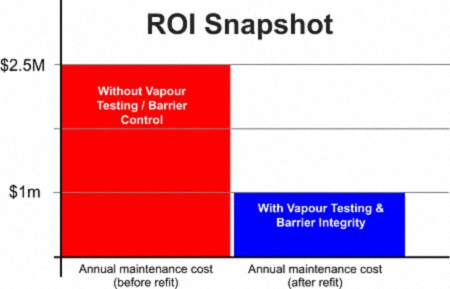

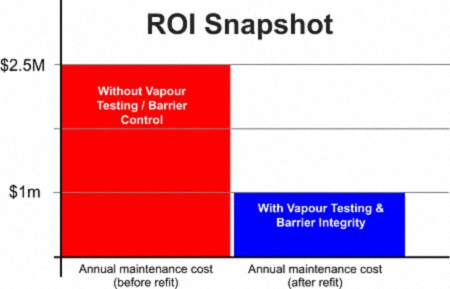

ROI Snapshot

Scenario |

Annual Maintenance Cost (per platform module) |

Without Vapour Testing / Barrier Control |

~USD 2.5M |

With Vapour Testing & Barrier Integrity |

~USD 1.0M |

Estimated Saving: ~USD 1.5M per module per year (~60% reduction).

Relevant Standards and Best Practices

- ASTM E96 – Water vapour transmission testing of materials.

- ISO 15106 – WVTR testing for films and sheeting.

- ISO 12241 – Thermal insulation for building equipment and industrial installations.

- DNV-RP-D101 – Guidance on CUI and fireproofing, including vapour barrier considerations.

- AMPP SP0198 (formerly NACE) – Design and maintenance standards for CUI control.

- DNV-GL / Lloyd’s Register guidelines – Additional marine-specific requirements.

Conclusion

For offshore platforms, vapour permeability is more than a material property — it is a critical driver of integrity, safety and lifecycle cost. Effective control requires robust vapour barriers, closed-cell insulations, proper design at joints and access points and adherence to rigorous standards. When combined with advanced inspection methods and digital asset integrity platforms, operators can detect risks earlier, extend asset life and reduce the high costs of corrosion under insulation.

Introduction

Introduction Technical Lessons Learned: Vapour Permeability and CUI on Offshore Platforms

Technical Lessons Learned: Vapour Permeability and CUI on Offshore Platforms