PRESS RELEASE

WHEN COSMETICS NEED TO LAST

Click for a print quality copy |

With the traditional role of glass packaging being taken over by flexible plastics, new factors become critical in preserving their content over periods of time. As glass and plastics react in very different ways, not only must the new containers be excellent at keeping volatile compounds in, but water and oxygen must be excluded to prevent the growth of micro-organisms and to protect a cosmetics delicate unsaturated lipid bonds, which can easily turn rancid and produce strong, unpleasant odours. |

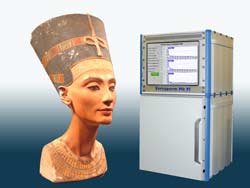

The key lies in the barrier properties of the packaging. And that’s where Versaperm can help with its technology-leading permeability measuring equipment. The equipment can measure both the permeability of the packaging material itself and also for the final manufactured container, which can easily be over four times less effective due simply to the manufacturing process.

Versaperm’s meter allows the most appropriate materials and manufacturing processes to be chosen and quality checked. The system can be configured for water vapour, as well as Oxygen, CO2, solvents, volatiles and most other gases.

Accuracy is typically in the parts per million range, (parts per billion for some gases and materials). This precise value of the permeability is critical not just to protect the contents, but it can also be the crucial factor in printability, and thus the marketing appeal of the product.

The meter can be used on a very diverse range of materials, as well as bottles, tubs, tubes, sachets, foils and laminates. It can be used during both product development and quality control. Versaperm also offers a consultancy and a permeability laboratory service for companies that only need to test samples on an irregular basis. |

ENDS |