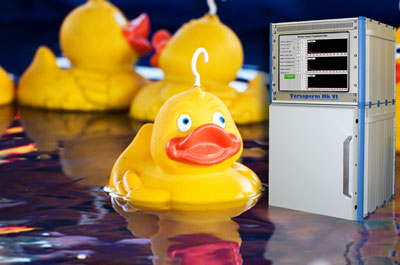

PLASTICS & RUBBER – DO YOUR PROFITS JUST LEAK AWAY?

Click

on the image to download a print quality scan

Despite being water and liquid proof, countless plastic and rubber products are very poor gas barriers, so water vapour and gases can pass through them anyway. And this not only means they leak, but it affects the plastics physical characteristics as well – particularly for coatings, materials handling and print quality.

Now, thanks to advances at Versaperm, measuring this effect (called permeability) has become easy, not just for water vapour, but also for hydrocarbons, solvents, oxygen, nitrogen, CO2 and most other gases or vapours.

Versaperm’s permeability meter is amongst the most technically advanced in the world, yet is fast and easy to use, with accuracies typically in the parts per million or parts per billion range. It can be used on most plastics and rubber samples as well as finished manufactured products and components.

Understanding the permeability of plastics, compounds, films and laminates can reduce several widespread problems - from drugs that lose potency to photocopiers that jam and food that goes stale. It also allows companies to design packaging that actively extends the shelf life of degradable products.

As well as manufacturing the instruments, Versaperm offers a permeability laboratory service for companies that need to test samples on an irregular basis.

ENDS

Please send

any sales enquiries to Christopher Roberts, Versaperm Limited ,

10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK, Tel: +44 (0) 1628 777668,

e.mail info@versaperm.co.uk

Web http://www.versaperm.co.uk

For further

Press Information please contact Gerry Palmer @ the Palmer & Rose

Partnership. Tel +44 (0) 1494 637499, e.mail gerry@palmer-rose.co.uk.

|