PRESS RELEASE

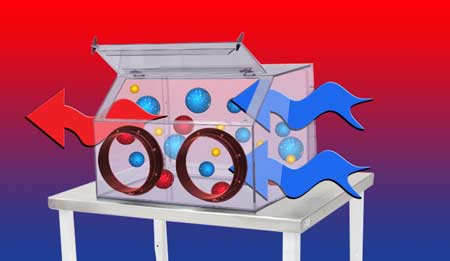

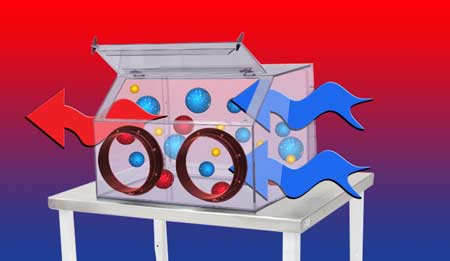

The critical importance of vapour permeability in Glove Boxes

Click

on the image to download a print quality scan

Glove Boxes are designed to control an internal gas environment, usually purified in some way. Any high concentration of a gas within any chamber will migrate or permeate out through the container itself – just as impurities will permeate in – no matter how "leak tight" you make it. And to complicate the matter the rates of permeation will vary for every gas.

This can cause massive problems, to reduce them you need to be able to measure the vapour permeability of the glove box and its materials against a wide range of gases and vapours. Fortunately the Versaperm GB is designed to do just this.

Versaperm equipment can produce fast results in these areas, sometimes in as little as thirty minutes. Measurements are accurate in the PPM (Parts per Million) to PPB (Billion) range. The equipment can optionally measure permeability for any gas in commercial use, including hydrocarbons, water vapour, nitrogen, hydrogen, ammonia, sulphur dioxide, oxygen and CO2.

The equipment has an automated user interface, is simple to use and can measure the permeability of both individual material samples, finished components and entire enclosures. Samples can range in size from a thimble to a pallet load.

Versaperm also runs a technical consultancy and a laboratory permeability measurement service for companies where the volume or logistics of measurements does not demand a dedicated instrument.

ENDS

Please send

any sales enquiries to Christopher Roberts, Versaperm Limited ,

10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK, Tel: +44 (0) 1628 777668,

e.mail info@versaperm.co.uk Web http://www.versaperm.co.uk

For further

Press Information please contact Gerry Palmer @ the Palmer & Rose

Partnership. Tel +44 (0) 1494 637499, e.mail gerry@palmer-rose.co.uk.