Defects including foam streaks, pinholes, bubbles, pits and other manufacturing defects are common in thin laminates and coatings. These defects significantly downgrade the material's performance, aesthetics, and durability. Errors can usually be picked up quickly with regular vapour permeability measurements.

Defects including foam streaks, pinholes, bubbles, pits and other manufacturing defects are common in thin laminates and coatings. These defects significantly downgrade the material's performance, aesthetics, and durability. Errors can usually be picked up quickly with regular vapour permeability measurements.

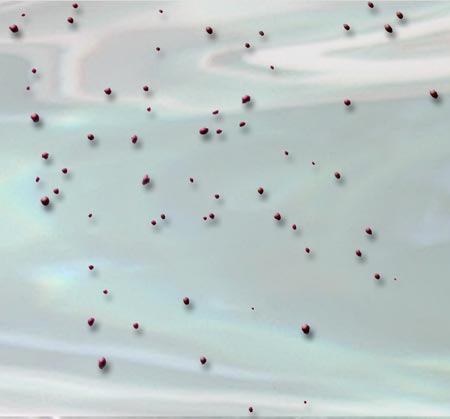

Pinholes are tiny, holes that appear on the surface of a coating. They can either stretch through the complete thickness of the coating or simply be shallow surface defects and allowing moisture, chemicals, or gases to penetrate, leading to corrosion or degradation.

They are created in several different ways, including:-

Contamination: Dust, dirt and other contaminants on the surface before application.

Incomplete Wetting: If a coating material doesn't properly wet the surface, small voids can form, leading to pinholes.

Outgasing: Volatile substances or trapped air in the substrate or coating can cause bubbles that pop, leaving behind pinholes.

Improper Application: Poor technique during application, such as too fast drying or improper mixing of materials.

Pinholes are a particular problem for companies using or developing fast-drying, water-based coatings, especially those cured at high temperature or applied at high wet film thickness. Despite the fact that the mechanisms for bubble release from a film are not fully understood yet, there are other general methods for reducing their appearance such as reducing the coating’s film thickness or using slow (co)-solvents).

Streaks are lines or bands that in a coating that are introduced due to uneven distribution of the coating material. More specifically they are caused by:-

Poor Mixing: when a coating’s components are not mixed thoroughly, streaks can form due to the uneven distribution of ingredients such as pigments

Uneven application, such as overlapping brush or spray passes, can cause streaks.

Surface Tension variations across the substrate causes the coating to flow unevenly, leading to streaks.

Differences in drying rates across the material can also result in streaking.

Streaks can degrade the appearance of the coating and may indicate areas of inconsistent thickness, potentially leading to performance issues.

Bubbles are trapped pockets of air or gas within the laminate or coating. They can occur on the surface or within the layers of the material. Bubbles can occur because of:-

Bubbles are trapped pockets of air or gas within the laminate or coating. They can occur on the surface or within the layers of the material. Bubbles can occur because of:-

Outgasing where gases are released from the substrate or from within a coating during curing.

Air can become trapped during both the mixing or application process, again leading to bubbles.

If a coating cures too quickly, the air or solvents may not escape properly.

Environmental Factors such as high humidity, temperature fluctuations, or improper ventilation also contribute to bubble formation.

Bubbles weaken the coating, reduce adhesion and create entry points for water vapour and other contaminants can cause early failure.

Pits are small dips or cavities in the surface of a coating or laminate. They can vary in size and depth. The main causes of pits are:-

Surface Contamination such as dust or other particles will create pits it the coating material fails to cover them properly.

Rapid evaporation of the solvents in a coating can leave behind pits where the material shrinks.

Inadequate Surface Preparation including poor cleaning or roughness.

Errors during application such as poor spraying technique or inconsistent application thickness.

Pits reduces the smoothness and integrity of the coating, affecting both aesthetic and functional properties.

Prevention and Mitigation

To avoid these defects, correct surface preparation is essential, as are the use of good quality materials and correct application techniques. This includes controlling environmental conditions during application, ensuring thorough mixing of materials, and allowing adequate drying and curing time.

Regular inspection and vapour permeability testing during the coating or laminating process can also help identify defects early, allowing for corrective actions before the material is fully cured or put into service.