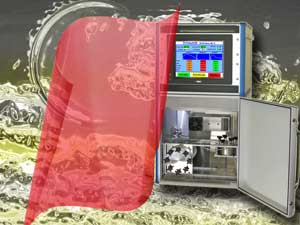

The Versaperm meter can be used to measure the permeability of the edible films products as well as for the packaging used for the finished product.

The Versaperm meter can be used to measure the permeability of the edible films products as well as for the packaging used for the finished product.

What can edible foods films for your products? - they can:-

Food makers and pharmaceutical companies can improve the shelf life and boost the quality of their products by controlling how the moisture and oxygen flow within their products. However, there are major differences between the permeabilities of the many available bio-based edible films, coatings and options that allow them to do this. Making the right choice is crucial, but not easy, as it also varies critically with the way the food is prepared.

Fortunately, Versaperm has developed a way that to measure the critical property reliably and accurately, using its latest range of permeability measurement equipment. Additionally, as permeability varies with the absorption and temperature of both the food and the coating, the equipment has an in-built oven which can mirror the cooking process.

Very basic overview of edible films:

Polysaccharides including cellulose, chitosan and starch and, proteins such a zein and collagen, and lipids such as triglycerides and fatty acids, can all be used as edible film-forming materials.

Polysaccharide films are low cost but only provide a low moisture barrier.

Protein films have good plasticity, elasticity, and good oxygen barrier properties but only offer poor water vapour resistance. Lipid films have good moisture barrier properties but poor oxygen barrier and mechanical properties.

For background on edible films click here or here

For equipment to measure permeability click here

For information on permeability testing click here

For background information on permeability click here

Vapour permeability is the measure of how strongly a material can resist the barrier passage of any gas (such as water vapour, Oxygen, CO2 or a hydrocarbon). Vapour permeability dramatically affects the physical characteristics of most products and materials, from outdoor clothing to missiles and from pizza to industrial seals.

The control of the transfer of moisture (ie permeability) throughout composite food products is the biggest challenge to food preservation. A wide range of edible film-forming compounds is available and this allows manufacturers and food producers to tailor moisture barriers to optimized their properties for each specific product. The only way this can be achieved is through the accurate measurement of the film or coatings permeability.