PRESS RELEASE

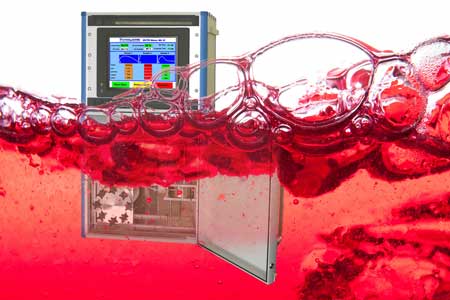

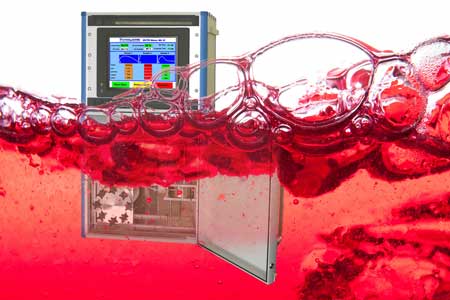

Do your fizzy drinks bottles go "Pop?" - CO2 and extending shelf life

Click

on the image to download a print quality scan

It can take just twelve weeks, from bottling a fizzy drink in a plastic bottle for it to lose around 15 percent of its fizz and sparkle (carbon dioxide). This damages the taste, the experience and the shelf-life. The CO2 simply permeates through the packaging, even when using materials like PET.

Versaperm's vapour permeability measurement equipment can help you solve this problem, no matter if you are producing beer, pop or any fizzy drink in a bottle, carton, keg or can.

There are two ways to do this. First you can create special "designer" laminated materials which are optimised to meet the differing needs of different bottle sizes, manufacturing processes, shapes and contents. And second you can instigate a high-precision quality control system on both the materials you use and, again, the manufacturing processes. Some thermoforming, for example, may increase the rate of gas loss by 400%.

Versaperm's latest ranges of equipment and sensors have been re-engineered to produce results with unprecedented speed and accuracy which help you understand the ways and rates that CO2 escapes from your bottles or containers. It also enables you to optimise both the design and manufacturing processes.

As different drinks require different permeabilities you can use the system to develop the best combination of materials for your specific products. For example, colas have around half the carbonation of ginger ale and different laminated products need to be used to optimise their containers.

During manufacture there is an almost inevitable drift of materials away from specification, which means you need to quality control the vapour permeability of your materials and containers to stop problems before they start.

Versaperm's equipment is fast, simple to use, accurate and can measure the permeability of any material sample, component or finished and filled container. It measures to an accuracy in Parts Per Million (PPM) to Parts per Billion (PPB) range.

As well as manufacturing and supplying equipment the company offers both consultancy and laboratory measurement services.

ENDS

Please send any sales enquiries to

Versaperm Ltd: 10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK,

e.mail: info@versaperm.com Web: www.versaperm.com

UK Tel: +44 (01628) 777668

USA Tel +1 (617) 855-7477

For Further Press Information please contact:

Gerry Palmer @ the Palmer & Rose Partnership

Tel +44 (0) 1494 637499

e.mail gerry@palmer-rose.co.uk