Polyethylene terephthalate (PET)is sometimes called Terylene in the UK, Dacron in the USAa and Lavsan in the former Soviet Union. It is strong, shatter and impact resistant and is very extensively used for making bottles and fibres such as clothing, boat sails etc.. It is probably the most widely used polyester as well as being the most recycled plastic in the world .

Polyethylene terephthalate (PET)is sometimes called Terylene in the UK, Dacron in the USAa and Lavsan in the former Soviet Union. It is strong, shatter and impact resistant and is very extensively used for making bottles and fibres such as clothing, boat sails etc.. It is probably the most widely used polyester as well as being the most recycled plastic in the world .

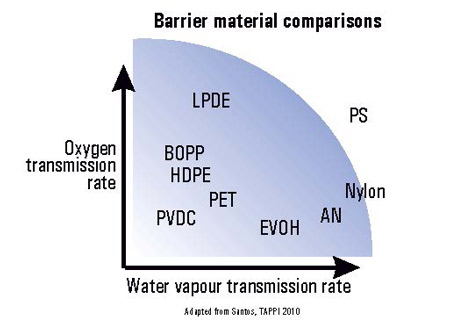

In all these applications one of its major physical properties is its resistance to various gasses (vapour permeability) as this controls its barrier properties and usefulness.

PET is well known for its high oxygen, carbon dioxide and water-vapour barrier properties, it offers effective electrical insulating properties as well as a wide temperature use range (-60 to 130°C).

PET is approved by safety agencies around the world including the FDA, it is lightweight and colourless and can be manufactured into both semi-rigid and rigid forms. Because it can be made into products offering good water vapour and alcohol impermeability, it is very commonly use to produce bottles where its high strength and impact resistance also becomes important. It also has good resistance to alcohols, aliphatic hydrocarbons, oils, greases and diluted acids as well as moderate resistance to diluted alkalis, aromatic and halogenated hydrocarbons. Additionally it is easy to convert to an opaque white material

As well as drinks bottles, clothes, fibres and textiles PET is used in containers for an extraordinary range of beverage, pharmaceutical medical and food products including carry-home food containers and prepared food trays that can be warmed in the oven or microwave.

This material is also widely used iin textiles creating strong, flexible, light-weight tear-resistant materials. It is widely used in electrical and electronics industries as well as for encapsulation, solenoids, smart meters, photovoltaics, and for some junction boxes.

Biodegradation

Biodegradation

PET can be biodegraded by a species of the Nocardia bacterium or processed and digested by the bacterium Ideonella Sakaiensis.

Products made from recycled PET include new PET bottles and jars, clothing, construction materials, carpets, automotive parts, strapping, rope, and packaging.application.

Click here for a technical description of designer coatings that will keep the carbonated "Pop" in the bottle and stop flavours going "off"

Click here for a press release on PET and Kevlar

Click here for application information on PET

Click here for Wikipedia's article on Polyethylene Terephthalate (PET)

Click here for Science Direct's page on PET