‘O’ MY GOODNESS

Why “O-rings,” seals, mastics and enclosures

let water in

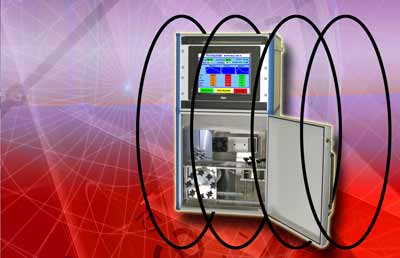

Click the photo to download a print quality copy of the

image

Almost all O rings, seals,

mastics and enclosures let water in. Most of them are excellent at keeping

liquid water out – but are very poor at sealing against water as

a vapour as it can pass straight through the material of many seals. But

how can you tell which is right for your purpose? Versaperm Limited, a

world leader in water vapour permeability measurement, has introduced

a quick and simple way to test this and overcome the difficulty.

Water vapour problems cost

the UK over £100M damage every year.

The new Versaperm’s MKVI

WVTR (Water Vapour Transmission) meter has been purpose designed for this

task. It can cope with several samples, seals or enclosures at a time,

often give a reading in as little as 30 minutes – whereas conventional

gravimetric measurements take several days and are significantly less

accurate.

Seals, mastics, adhesives,

gaskets, O-rings and enclosures can be highly sensitive to changes in

pressure, temperature and other conditions. Testing is the only way to

ensure that a seal is fit-for-purpose and that Quality Control is being

maintained.

The WVTR meter is easy to use

and gives a series of digital readouts that can be saved or simply read

off the screen. It needs no re-calibration and requires, at most, minimal

training to give results that can be as accurate to the PPM (parts per

million) or PPB (parts per billion) range depending on the gas used. The

instrument can be configured to measure not just water vapour but most

gaseous, including Hydrogen, Helium, Hydrocarbons, Oxygen, Nitrogen and

Carbon.

As well as manufacturing the

instruments, Versaperm offers a water vapour (and other gases) permeability

laboratory service for companies that need to test samples on an irregular

basis.

Common

O Ring materials

Aflas

FEPM

|

Resists oils, lubricants

and some fuels, it is suitable for use with H2S, amines

or high temperature water/steam.

|

Butyl

IIR

|

Offers low gas permeability

and is can be used for vacuum and high pressure applications.

It should not be used with mineral oils

|

| Epichlorohydrin

ECO> |

Provides good resistance

to mineral oils, fuels and ozone. Has poor compression set resistance.

|

| Ethylene-propylene,

EPM/EPDM |

Offers excellent resistance

to weathering, ozone, water and steam.

|

Fluoroelastomers.

Dyneon, Viton, Tecnoflon

|

Works well in severe

chemical conditions and high temperatures.

|

Fluorosilicone

FVMQ

|

Is extensively used

for static seals in aerospace as it is highly resistant to many

hydrocarbon types.

|

Hypalon

(and other chlorosulphonated polyethylenes)

|

Offers excellent resistance

to weathering and works well with many media for static sealing

duties.

|

Hydrogenated

nitrile, Elast-O-Lion

|

Offers good mechanical

and chemical resistance properties.

|

Kalrez

FFKM

|

These erfluoroelastomer

compounds have excellent chemical and temperature resistance (grade

dependant).

|

Natural

rubber

|

Strong with good abrasion

resistance, it is suitable for use with ammonia, ethylene glycol,

dilute acids and alkalis, though please note that synthetic rubbers

provide greater resistance to heat, weathering and oils.

|

Neoprene

|

A general purpose elastomer

that stands up well to sunlight and atmospheric ageing.

|

Nitrile

|

Widely used with mineral

oils water and some solvents, some grades are suitable for food

applications.

|

| Polyurethane |

Offers good mechanical

properties as well as resistance to weathering. hydrocarbon fuels

and mineral oils. Stress relaxation may occur above +50°C.

|

PTFE, Fluolion |

Offers excellent resistance

to most media and can also be used for 'O' ring back-up rings,

though flow characteristics limit its use.

|

|

Silicone |

Offers good heat and

weathering resistance as well as having excellent electrical properties.

Sealing ability is limited due to high gas permeability, low tensile

strength and poor resistance to tear and abrasion.

|

Copyright

Versaperm 2007: This table can be freely published as long as it is properly

credited to Versaperm Limited

ENDS

Please send any sales enquiries to Christopher Roberts, Versaperm Limited ,

10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK, Tel: +44 1628 777668

e.mail info@versaperm.co.uk Web http://www.versaperm.co.uk

For further Press Information please contact Gerry Palmer @ the Palmer & Rose Partnership. Tel 01494 637499, fax

0871 9003898,

e.mail gerry@palmer-rose.co.uk |